#Video processor gamma control tv

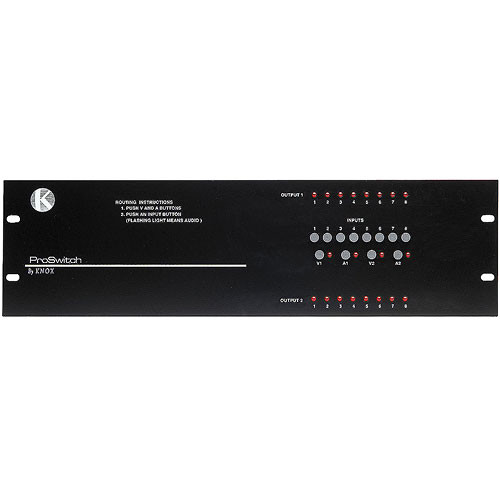

gamma., it is known, for example from the "One-chip TV processor" TDA 884X/885X-N1 from Philips, for a cutoff and drive control system designed as a two-point control system to define reference currents and reference voltages which respectively correspond to two different cathode currents, which are called the first and second reference cathode currents, I.sub.K1 and I.sub.K2, respectively, in the following text. This is subject to only relatively minor scatter for tubes with the same system design.Assuming a constant value for the characteristic exponent. For colour tubes that are known at present in the consumer area, the value of the exponent. since, from the definition of the reference voltages and currents, the "theoretical" characteristic exponent is also defined uniquely from the above equation. mu.A.Owing to the physically dependent beam-current characteristic profile I.sub.K =f (V.sub.K) as a function of the control voltage V.sub.K at the respective cathode of a colour tube, the following mathematical relationship may be used for the ratio of two cathode currents I.sub.K, based on the two-point control system: #EQU1#The described two-point control system is thus based on an "assumed" exponent. mu.A and I.sub.K2 (as I.sub.Drive).apprxeq.15. Values that may be used in practice are, I.sub.K1 (as I.sub.cutoff).apprxeq.7. Two different cathode control voltages V.sub.K1 and V.sub.K2, to which two different voltage levels of the respective RGB signal correspond, and two corresponding cathode currents I.sub.K1 and I.sub.K2 are defined as reference values-corresponding to the circuit concept used. Such a control system by means of two different reference values represents a two-point control system which, in practice, is formed by two control loops. Furthermore, there is no correction for any changes in the gain.Recent circuit concepts thus inject a further measurement line, whose amplitude is greater, into each colour channel for gain control, which is also known as drive control (for example so-called cutoff measurement lines in one field and so-called drive measurement lines in the other field, alternately). However, the control process cannot ensure that the actual black level of the signal corresponds to the cutoff points of the tube. A DC voltage offset, in practice equivalent to a brightness offset, is used to raise or lower the measurement lines for each colour channel in the event of a control error, in such a manner that the measurement currents correspond to the reference value. The cathode currents during the measurement lines are measured, and are compared with a reference value. To this end, measurement lines are injected in a sequential manner for the three colour channels, also called RGB colour channels, during the frame blanking period, and these measurement lines are normally equivalent to a relatively small signal amplitude so that the correction process is carried out to a value which comes as close as possible to the actual cutoff points of tube systems. This requires adaptation of the tube cutoff points-also called cutoff trimming-as well as a specific ratio of the cathode currents at a so-called white point, which can be achieved by means of an adjustment process which is known as gain or drive trimming.Control circuits are used in order, in particular, to keep the cutoff points of a colour tube stable, despite ageing.

It is based on a colour tube in a colour television set, and on projection tubes for displaying video signals.One precondition for correct colour-video reproduction is that monochrome pictures are reproduced with neutral colours. gamma.-dependent DC voltage offset u.sub.0f to zero.īACKGROUND OF THE INVENTIONThe invention relates to cutoff and gain control for a device for displaying video signals.

is defined as a function of the color tube 1.

Thus, according to the invention, the exponent. or for the ratio of the two cathode currents I.sub.K1 and I.sub.K2, it is not possible to achieve an optimum result for displaying monochrome pictures. However, it has been found that, if a fixed value is assumed for the exponent. or of the ratio of the two cathode currents I.sub.K1 and I.sub.k2. of the characteristic profile and the ratio of two cathode components I.sub.K1 and I.sub.K2 may be used to form control reference values for cutoff and drive control, this process being started in each case from a fixed value of the exponent. Owing to the physically dependent exponential beam current characteristic profile as a function of the cathode control voltage V.sub.K, the exponent. Recent circuit concepts inject measurement lines, for cutoff and drive control of the cathode current, into each color channel during the vertical frame blanking period.

0 kommentar(er)

0 kommentar(er)